Beam

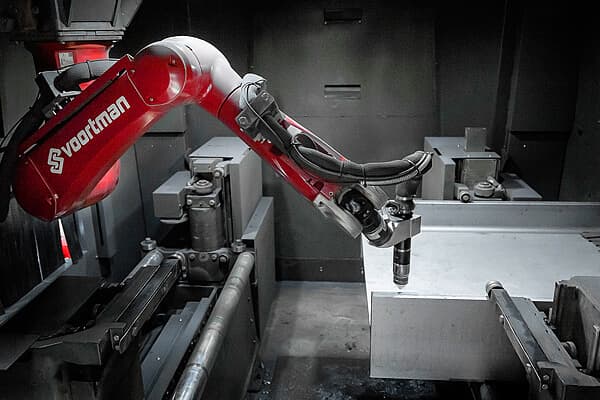

Gulf States Saw & Machine Co has been the market leader in 3D pipe profilers for over 35 years. We were the first to introduce a robotic beam profiling device with reliable profiling capabilities that can cut all slots, chamfers, and saddles: the RPC 1200 Mk3 A beam coping machine that can profile beams, channels, square tubes, angles bars, and square tubes has been a long-standing market demand. It also profiles pipes, plates, Tbars, and bulbs.

This plasma drilling machine has been designed to incorporate as many fabrication functions as possible into one machine. The PCR41 is able to produce completely finished parts at the lowest possible manufacturing costs. This machine automates all cutting operations typically performed and structural steel.